outline

The high elasticity liquid roll body is a styrene butyl styrene styrene styrene (SBS) copolymer thermoplastic elastomer modifier to modify the excellent petroleum asphalt, and add a variety of rubber, synthetic resins, surfactants, emulsifiers, antifungal agents and other auxiliary materials, refined by special equipment, ultraviolet resistance and high and low temperature, high elongation of the coating film and super adhesion, good deformation to cracks, and a new type of high-efficiency waterproof coating that combines all the advantages of quick-setting spraying and non-fixed line coatings.

Key features:

Excellent performance: good cold resistance, heat resistance, corrosion resistance, strong adhesion;

Easy construction: The product is a water emulsion material, which can be applied on a variety of irregularly shaped substrates.

Cold construction, short construction period;

Strong adhesion: It can be constructed on the surface of damp and waterless concrete, asbestos board, various metals, wood, plastics, etc., and can be used in combination with other waterproof materials;

Convenient maintenance: local damage and leakage, local maintenance thickness can be directly used for caulking sealing, and can also be used for metal anti-corrosion;

Environmental protection: The product does not contain tar and is an environmentally friendly product.

Scope of application

It is mainly used for flooring, industrial and civil building roof and side wall waterproofing projects; planting roof waterproofing works; waterproofing works for underground structures, subway stations, tunnels, etc.; waterproof projects such as roads, bridges, railways, etc.; waterproofing projects such as dams and water conservancy facilities;

Technical Indicators

Inspection items, technical indicators, inspection results, judgment

Paint film color and appearance Brown-black Brown-black Qualified

Viscosity, S 50 65 qualified

Solids, % 70 78 Pass

Drying time (h) Surface dry ≤4 2.6 qualified

Practical ≤24 18 qualified

Hardness ≥0.56 0.83 Passable

Adhesion, grade ≥1.0 1.5 qualified

Flexibility (mm) ≥1.0 1.6 qualified

Chemical resistance, acid resistance, 60 °C, 20% sulfuric acid, no change for 7 days, no change, qualified

Alkali resistance 20% sodium hydroxide solution has no change for 7 days No change Qualified

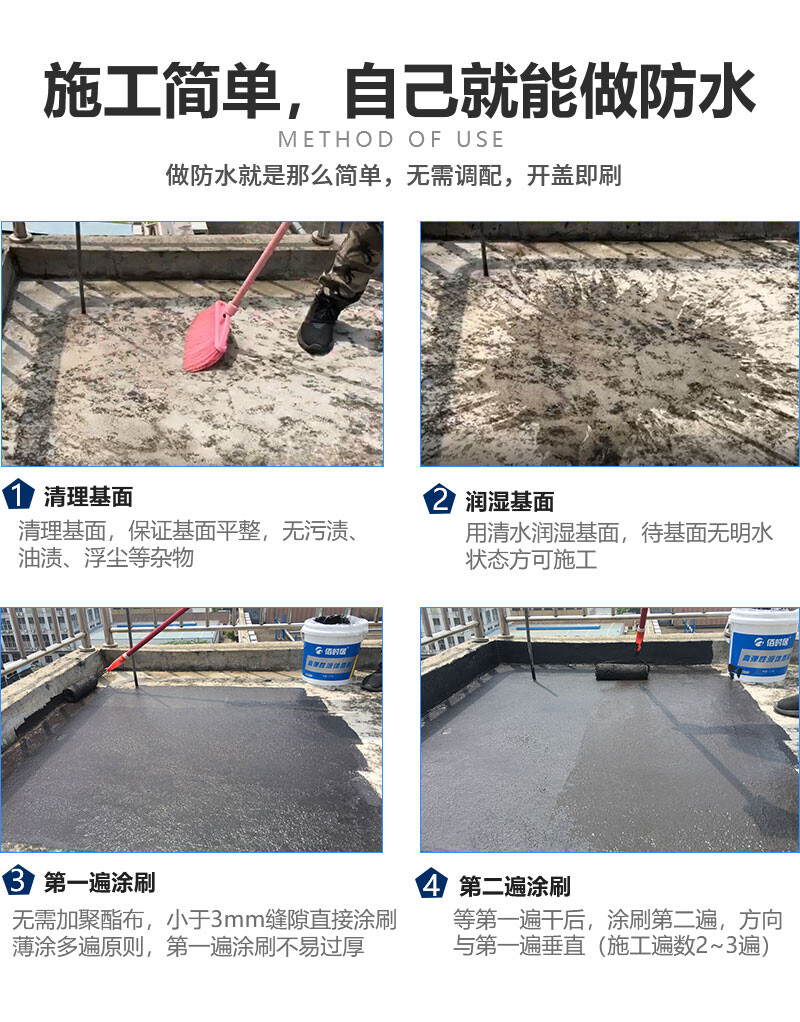

Construction method

1. Clean the base surface and keep the base surface clean, no dust, no oil stains, flat and no falling off

2. Wet the base surface with clean water, and wait for the state of no open water before construction

3. The principle of thin coating multiple times, the first time to paint, evenly painted in the same direction

4. Wait for the first time to dry, do not stick to the state before the second time to paint, the second time direction is perpendicular to the first time (recommended construction 2~3 times)

5. Allow to dry completely (at least 48 hours later) as a protective layer

MESSAGE

It's better to leave your contact information, let's have a chat!